In the world of 3D scanning, precision is paramount, and achieving it often involves more than just the capabilities of your scanner. The strategic use of 3D scanning spray is an art that, when mastered, can significantly elevate your scanning results. This comprehensive guide not only provides a step-by-step walkthrough for the optimal application of 3D scanning spray but also delves into essential best practices that can refine your 3D scanning process. From meticulous part cleaning to the seamless self-sublimation of the matting film, each step and best practice contributes to the excellence of your 3D scans.

-

Clean the Part for Prime Scanning: Begin your 3D scanning process by ensuring your part is free from moisture, grease, or any lingering residue. Beyond mere equipment care, this thorough cleaning process sets the stage for superior 3D scanning results. A pristine surface not only facilitates accurate data acquisition but also minimizes potential interference during the scanning process.

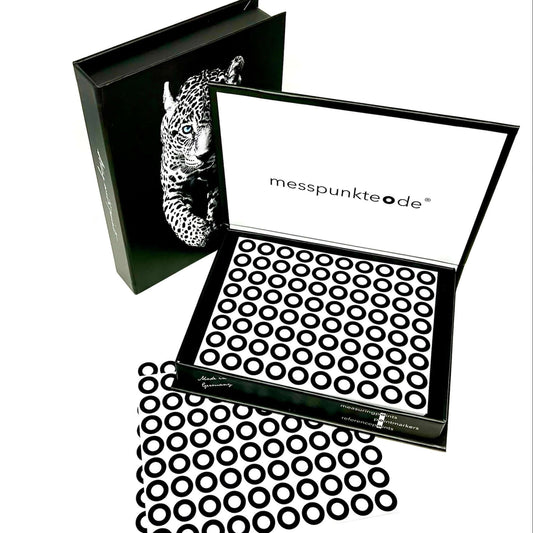

Best Practice: Sample Testing Before applying the scanning spray to the entire object, conduct a test on a small sample or an area of the part to scan. This practice helps determine the optimal amount of spray required and ensures compatibility with different materials.

-

Shake the Can for Optimal Formulation: Shake vigorously for at least 30 seconds. This action guarantees the optimal mixing of the matting agent, enhancing its effectiveness during application. Properly mixed spray ensures consistent results across the surface, laying the foundation for precise 3D scans.

Best Practice: Environmental Considerations Take note of environmental factors such as temperature and humidity, as they can influence the sublimation time. Conduct tests in varying conditions to understand their impact on the overall process.

-

Apply Scanning Spray with Precision: Maintain precision during application by keeping a distance of 6 to 10 inches (15 to 25 cm) between the can and the part. This ensures an even coating, preventing excessive buildup and guaranteeing uniform coverage. Consistent application is key to facilitating an accurate and reliable 3D scan. For most applications, a single coat will be sufficient to provide the necessary surface matting for accurate scanning.

Best Practice: Uniform Application Maintain a consistent distance and speed during spray application to achieve a uniform coating. This practice minimizes the risk of over-application and ensures even coverage.

-

Allow Matting Film to Form: Post-application, exercise patience and allow the matting film to form. This waiting period, lasting between 15 seconds to 1 minute, lets the spray settle and create an even coating on the surface. The matting film acts as the foundation for accurate data capture during the subsequent 3D scanning process.

Best Practice: Proper Ventilation Ensure proper ventilation in the scanning area to avoid breathing the chemicals used in the spray for the sublimation. Note that higher airflow can lead to faster sublimation.

-

Initiate 3D Scanning Process: Once the matting film has formed, proceed with the 3D scanning process. Follow your scanning equipment's guidelines to capture the entire surface of the object. The meticulous preparation undertaken in the previous steps ensures precise and high-quality 3D scan data.

Best Practice: Calibration Checks Regularly calibrate your 3D scanner to maintain accuracy. Changes in the scanner's calibration can impact the effectiveness of the matting agent, leading to less-than-optimal results.

- Film Self-Sublimates for Seamless Finish: Experience the seamless finish as the matting film self-sublimates post-scanning. The sublimation time varies based on surface finish and ambient conditions. This feature eliminates the need for additional cleaning steps, ensuring a smooth transition from scanning to final results without residue or interference.

Incorporating these steps into your 3D scanning routine ensures not only optimal results but also a streamlined and efficient workflow. From the initial cleaning to the self-sublimation of the matting film, each stage is crafted to maximize accuracy and precision in your 3D scanning endeavors. Elevate your scanning experience by adhering to these guidelines, unlocking the full potential of your 3D scanning spray for superior results.