How to apply positioning target dots for 3D scanning

Share

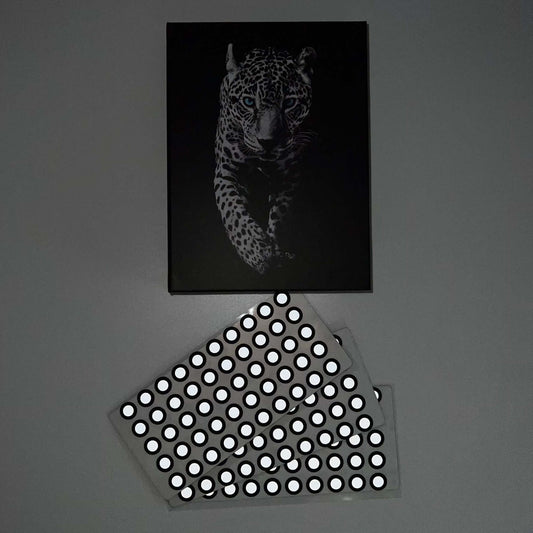

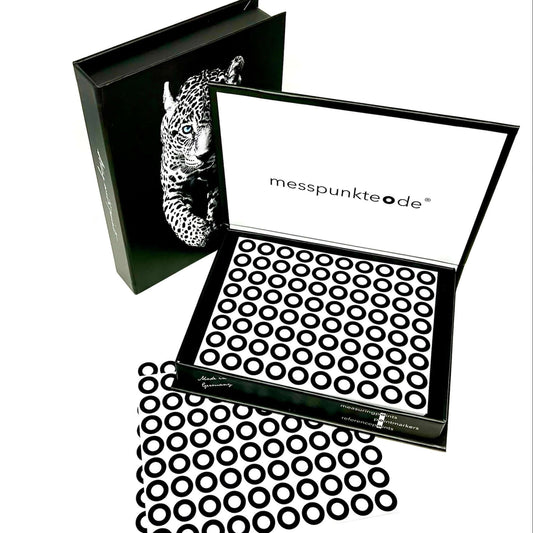

Target dots, also known as reference markers or fiducial markers, are small objects placed on a surface to provide a point of reference for 3D scanning equipment.

Reference markers play a crucial role in 3D scanning, allowing for accurate and consistent measurements. Without proper reference points, the resulting scan can be distorted or inaccurate. This article will provide an overview of the different types of target dots available, the factors to consider when choosing the right type for your application, and best practices for applying target dots to ensure successful 3D scanning results.

How to apply target dots

- Surface preparation. The surface where target dots will be applied must be clean and free of any debris or contaminants.

- Dot placement. Target dots should be placed strategically to provide reference points for the scanner to accurately capture the geometry of the object being scanned.

- Dot density. The density of target dots should be high enough to provide adequate reference points but not so high that they interfere with the scan. A good rule of thumb is so the scanner "sees" around 5 targets at all time within its field of view.

- Dot size. The size of target dots should be appropriate for the size of the object being scanned and the scanning technology being used. Refer to the scanner manual for more information

- Dot type. The type of target dot chosen should be suitable for the application and the surface being scanned.

This article explains how to chose the right target size and type for your specific application.

Tips for successful application

Minimizing the impact of environmental factors Factors such as lighting, temperature, and humidity can impact the accuracy of the scan. Taking steps to minimize these factors can improve results. Reducing noise and interference in the scanning environment can also improve accuracy. Techniques such as multiple scans or using different types of target dots can help improve results. Common mistakes when applying target dots include using too few or too many, using the wrong type for the application, or not properly cleaning the surface before application leading to dots moving or detaching.

Conclusion

Target dots are essential for accurate 3D scanning and choosing the right type and properly applying them can improve results. Proper target dot application can significantly impact the accuracy and quality of 3D scanning results. For more information or assistance with applying target dots for 3D scanning, contact a metrology equipment supplier or 3D scanning expert.