How to 3D scan shiny or transparent parts?

Share

Precision in 3D scanning of transparent or shiny parts demands a nuanced approach due to inherent challenges such as reflections and a lack of surface features. In this guide, we explore the intricacies of 3D scanning, providing a methodical framework to overcome complexities and achieve accurate scans for objects with elusive properties.

1. Understanding the Challenges: Transparent or shiny parts introduce challenges in the form of reflections and limited surface features. These complexities necessitate a nuanced understanding to develop targeted strategies, acknowledging the limitations of traditional scanning methods.

2. Selecting the Right 3D Scanner: Choosing a suitable 3D scanner is foundational for successful scans of transparent or shiny parts. Opt for scanners equipped to handle reflective surfaces and transparent materials, such as high-end structured-light scanners or laser scanners, ensuring precise data capture.

3. Surface Preparation: Thorough surface preparation is pivotal for accurate scans. Utilize 3D scanning spray to create a uniform surface, minimizing reflections and enhancing the precision of the scanning process. Tailor the preparation technique based on the specific properties of the material. Check out this article on best practices for applying 3D scanning spray.

4. Lighting Techniques: Employ advanced lighting techniques to mitigate challenges posed by transparent or shiny surfaces. Strategies such as diffused lighting and strategic backlighting play a crucial role in reducing reflections and illuminating surface features, contributing to more accurate results.

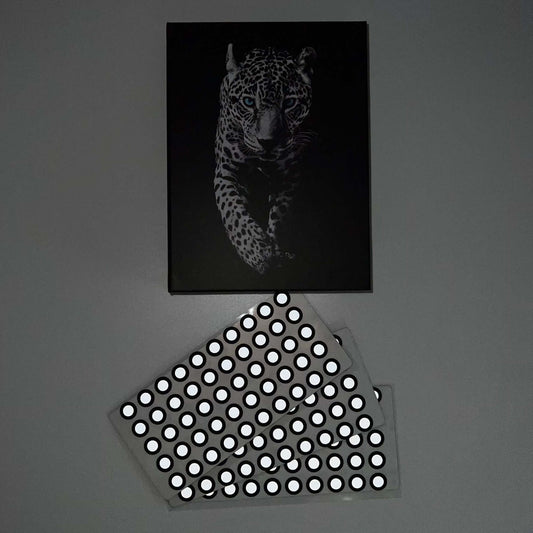

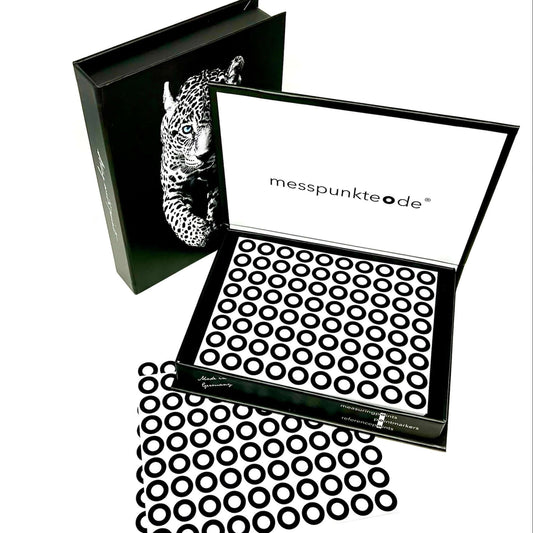

5. Scanning Strategies: A strategic scanning approach is fundamental for success. Implement multi-angle scanning to capture data from different perspectives, compensating for distortions and enhancing overall accuracy. Incorporate reference markers to facilitate alignment and comprehensive coverage.

6. Post-Processing: Post-processing serves as a critical step in refining scans. Utilize software solutions capable of compensating for reflections, manipulating scan data, and creating watertight meshes. Detailed post-processing techniques ensure the transformation of raw scans into accurate and usable 3D models.

In the world of 3D scanning, the intricacies of capturing transparent or shiny parts require a disciplined approach. By leveraging precise tools such as 3D scanning spray and reference markers, professionals can navigate the challenges of reflections and limited surface features. The strategic use of advanced lighting techniques, meticulous scanning strategies, and thoughtful post-processing ensures the transformation of raw scans into accurate 3D models. As technology evolves, staying abreast of advancements contributes to the continual refinement of scanning methodologies. The pursuit of precision in 3D scanning for such materials is a journey marked by adaptability, innovation, and a commitment to overcoming inherent complexities, ultimately opening new frontiers in diverse industries.